Sheet Metal Work for the UK Lighting Industry

Bespoke sheet metal fabrications

Sheet metal is a versatile material that can be used to create a wide variety of lighting products, from simple light fixtures to complex architectural lighting systems. In the lighting industry, sheet metal is used for a variety of purposes, including:

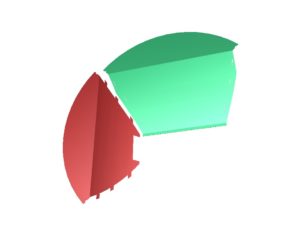

Reflectors: Reflectors are used to direct light in a specific direction. They are often made from polished aluminum or stainless steel, which can reflect light with high efficiency.

Diffusers: Diffusers are used to soften or spread light. They are often made from translucent materials, such as acrylic or polycarbonate.

Housings: Housings protect the electrical components of a lighting fixture. They are often made from sheet metal that is painted or powder-coated to match the fixture’s finish.

Brackets: Brackets are used to support lighting fixtures. They are often made from sheet metal that is bent and welded into the desired shape.

Exhaust grilles: Exhaust grilles are used to ventilate lighting fixtures. They are often made from perforated sheet metal that allows air to pass through while still preventing insects and other debris from entering the fixture.

Sheet metal work for the UK lighting industry requires a high degree of precision and skill. The sheet metal must be cut, bent, and welded to exact specifications in order to create a finished product that meets the desired performance and aesthetic requirements.

Laser cut zintec components TiG welded together to construct industrial light fittings

There are a number of different sheet metal fabrication techniques that can be used for lighting products. Some of the most common techniques include:

Laser cutting: Laser cutting is a precise and efficient way to cut sheet metal. It is often used to cut complex shapes and patterns that would be difficult or time-consuming to cut using other methods.

CNC punching: CNC punching is a fast and accurate way to create holes in sheet metal. It is often used to create rows of holes for mounting screws or other fasteners.

Press brake bending: Press brake bending is a versatile process that can be used to bend sheet metal into a variety of shapes. It is often used to create curved reflectors and diffusers.

Welding: Welding is used to join two pieces of sheet metal together. There are a variety of welding methods that can be used, depending on the specific application.

The choice of sheet metal fabrication technique will depend on a number of factors, including the size and complexity of the part being made, the desired level of precision, and the budget.

Sheet metal work is an essential part of the lighting industry. By using sheet metal, lighting manufacturers can create products that are both functional and aesthetically pleasing. The use of advanced sheet metal fabrication techniques ensures that lighting products meet the highest standards of quality and performance.

Reflector slots and tabs

Here are some additional benefits of using sheet metal for the UK lighting industry:

Durability: Sheet metal is a strong and durable material that can withstand a variety of environmental conditions. This makes it ideal for use in outdoor lighting fixtures.

Affordability: Sheet metal is a relatively inexpensive material, which can help to keep the cost of lighting products down.

Recyclability: Sheet metal is a recyclable material, which helps to reduce environmental impact.

If you are looking for a versatile, durable, and affordable material for your next lighting project, consider using sheet metal. With the help of a skilled sheet metal fabricator, you can create lighting products that meet your exact needs.

Past examples of UK Lighting Projects

More detailed data on lighting sheet metal work.