Just 3 examples of the hundreds of sheet metal projects we have been manufacturing this month in Fareham, Hampshire.

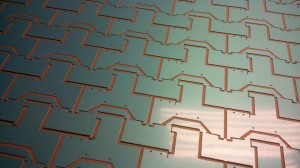

CNC punched pre-anodised aluminium reflector material

Lighting reflector CNC punched blanks

We have CNC punched out a range of small lighting reflectors from 0.4mm thick pre-anodised alanod reflector aluminium. The material comes with a peelable plastic film which we keep on the material throughout the manufacturing process to maintain a clean and scratch free surface on the presentation side of the material. With all reflector materials whether they are highly polished such as Miro4 or satin as this material they can show finger marks so easily so they have to be handled very carefully. The reflectors were CNC punched on our slower punch press, the Trumpf 200. This is perfect for this process as the material is so thin and delicate that the slower gentle punching suits the sheet metal nest once it has become fragile towards the end of the program. You can see that the material yield is good on the sheet whilst still maintaining a practical program in production.

Aluminium assemblies MiG welded together

Aluminium MiG welded chassis assemblies

Here we have manufactured a batch of aluminium chassis assemblies from 3mm 1050a aluminium alloy. The manufacturing techniques have included CNC punching, edge deburring, bush insertion, sheet rolling, CNC bending, aluminium MiG welding and cleaning up. These welded fabrications are then powder coated and used within the assembly of a scientific instrument.

Zintec chassis parts laser cut and CNC bent

Zintec folded sheet metal end plates

These Zintec (zinc coated mild steel) end plates have been manufactured using laser cutting and CNC bending techniques. These parts are among the first sheet metal components that we have manufactured on our new Trumpf 3030 3KW fiber laser machine. The parts were laser cut with compressed air as the assist gas which removed the need to deburr the cut edges that would have been done under CNC punching. The final finished parts were powder coated and then used in a pump assembly for the brewery industry.

Go an idea that you may want to have manufactured in sheet metal or need a bit of advice?

Give us a call or send an email and our engineering team will take a look for for you.