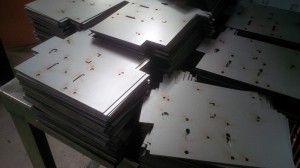

Mild steel laser cut chassis blanks

Here’s another nice example of laser cutting and bending technology from Trumpf working together to make for an efficient production capability at V and F sheet Metal. We have just produced a batch of 2000 1.5mm thick mild steel chassis blanks on our Trumpf 3030 3KW fibre laser using oxygen as the assist gas. The chassis blanks were produced so cleanly that no edge deburring was needed after laser cutting. The chassis blanks shown here have slight signs of burning from the laser cutting process but this isn’t important as the acid treatments when they are being zinc plated will clean all this off the surface producing a perfect shiny finished component. As ever with laser cutting there were no tools involved and our customer has made several changes to the design with no price impact for them. The next process is to bend the chassis blanks up into there finished form.

Bending mild steel chassis components

The bending process is relatively simple and very quick with a Trumpf 7036 CNC press brake. We have made these chassis components before so the CNC program was already stored on our system server and it was a simple matter calling it back up. The tooling needed, position of the tooling and all bend sequence information is saved for the machine setter to use and then the machine operator to follow in producing each chassis component. A 3D graphic image with each bending stage can be viewed to ensure that the component is bent up correctly ready for inspection. Once the machine is set the Trumpf 7036 is very quick in producing each bend. The sequence of bends is repeated for each component until the batch is completed. The efficient ergonomic layout of the CNC press brake enables an operator to sit at the machine close to the tooling but still safe with the use of laser guards. The machine has it’s own lighting and adjustable work table for optimal position and enabling the operator to work without strain on longer batches of sheet metal work.

Finished mild steel chassis components

The final finished sheet metal chassis are stacked within arms length and at the same height as the bending area to minimise movement and speed up the process. The consistency of laser cutting and CNC bending using Trumpf equipment nicely is demonstrated here.

You may have a sheet metal chassis that you want pricing, it might need CNC punching, laser cutting and CNC bending. We are happy to take a look for you and produce prices and suggest ways that the component can be improved for manufacturing to save you money. Please give our team a call on 01489 577786 or send us an e-mail.