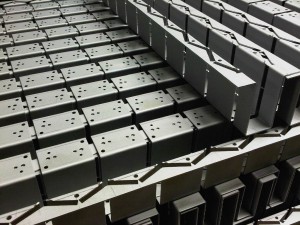

Folded Zintec channels

Here’s a great little idea to save money on sheet metal brackets. We have CNC punched out bracket profiles with all their holes but left them still tagged within the parent sheet metal in separate panels. We have then bent them up in rows of 10 at the same time saving a lot of folding time. The final banks of 10 brackets are sent like this to the customer who can keep them on the shelf and break them out by simply twisting the channels of brackets whenever they want them. The only downside to this method of production is that we cannot deburr the edges as they are still within the folded channel when they are sent out but if you are happy to work with this then it’s a simple idea to save money and well worth considering for components with a consistent cross section.

Please give us a call if you think we might be able to help you with this technique and we will be happy to take a look at your designs for you.

Folded stainless steel housings

Stainless steel housings with folded sides and safe edges all around the tops. The safe edges have been produced by over bending to a 30 degree inclusion angle and then as a separate operation closed down with a flat bottomed CNC press brake tool. Once the housings had been folded up with close touching corners the corners joints were seam welded up and then cleaned off smooth before powder coating. These stainless steel housings are typical of the work we manufacture on Fareham, Hampshire, UK with batch of between 50 to 100 off.

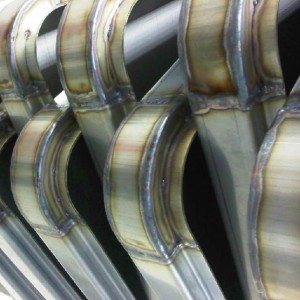

Folded housings with multi-bend curved corners

CNC bending is great at producing straight bent sections. These can be just a slight touch of the sheet producing a 179 degree inclusive angle stiffening bend in large lids etc to stop them panting. Many parts are bent are 90 degress such as support angles, brackets, boxes and lids. Some as the example above can be safe edge profiles where the material is folded right back round on itself. There is another technique that can be carried out when bending sheet metal and that’s multi-bending. Multi-bending can be used to produce curved sections by using a series of small bends at regular intervals to simulate a curve by producing the flats as a tangent to the curve circumference. The advantage of this manufacturing method is the flexibility to use standard press brake top and bottom V tools to produce whatever radius of curve that is needed. This also allows us to modify the program if there are design changes and to deal with variations in material from batch to batch which can be a problem with fixed shape tooling. These parts have been produced on our Trumpf 7036 CNC press brakes which are the perfect machine for this type of work.