Laser cutting in progress.

Using a Trumpf 3030 fibre laser for laser cutting thin gauge sheet metal is absolutely perfect. Being a fibre laser source the machine is extremely fast when cutting sheet metal below 3mm. Easy and cheap to run. Easy to CNC program and ideal for sub-contract sheet metal manufacturing where you never know what you will be asked to make next.

Parts removed for inspection

When laser cutting thin gauge sheet metal brackets the production team have some control over the parts they produce. At the start of a new batch the laser cutting machine can be stopped and parts can be removed. They can be inspected visually to check that the laser cut is clean. They can also be measured to ensure they are to drawing. In both cases adjustments can be made at the machine to influence the finished parts. This can be adjustments to the gas flow rate, feed rate of the machine, power of the laser beam and focus position. We can also adjust the cutting offset at the machine so component profiles and hole sizes can be tuned to achieve the drawing tolerances required. All this without having to talk with the CNC programmer saves time and enables the production staff to make their own decisions in real time.

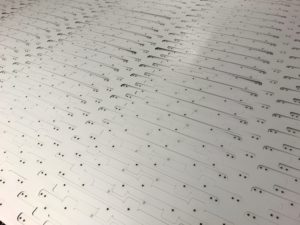

Full sheet of laser cut brackets

Using our Radan CAD/CAM software enables us to produce very efficient nest layouts. Once a blank has been programmed it’s very simple to fill a standard or off cut sheet with as many parts as possible. Not only does this save money on material when quoting for new projects but it also enables us to reduce waste by using up off cuts from previous projects. Looking at the image here and the magnified image you can see just how fine laser cutting thin gauge sheet metal can be.

Laser cut brackets in detail

Parts such as these brackets are long enough to simply leave on the bed of the machine. No corner tags are needed. No time consuming breaking out of parts from the sheet nest and no edge de-burring. We simply pick the parts from the sheet and then lift the scarp skeleton off the bed. All this can happen while the laser machine is cutting the next sheet so that production is not interrupted.

Laser cut scrap nests

All the scrap sheet metal is collected together and separated into different grades. Stainless steel, aluminium, mild steel along with Zintec and galvanised steel, copper and brass. That way we manage to recycle 100% of the scrap metal we produce. Another advantage of laser cutting is that all the scrap sheet is dry and easy to handle.

If you have a project that requires sheet metal brackets please give us a call. We will be happy to help you out and produce price options to suit your order volumes.