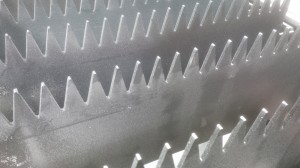

Slats with slag fused on

Here’s an image of our Trumpf 3030 fibre laser pallet changer being cleaned with a special purpose machine. You can see that over time using a laser cutting machine builds up area of slag that is fused hard to the bed slats. This slag doesn’t stop us putting sheet metal on the slats and cutting it but it does reduce the quality of the cut. The image here isn’t too bad but over time the small ends of the slats can grow many time larger and produce a poor laser cut finish.

Slat cleaning on a Trumpf 3030 pallet changer

Using a special machine (TruToll TCS 100) from Trumpf we are able to clean the majority of the accumulated slag from the slats as part of our machine maintenance program. The machine vibrates 2 sets of hardened jaws that chip the slag off each side of the laser bed slats. The cleaner the bed slats can be the better the laser cut finish of the component will be.

Clean slats with no slag build up

With clean slats there is only a small area of contact between the underside of the sheet metal being laser cut and the top of the slats. The smaller the area of contact when the laser head / beam passes

over the smaller any burn mark might be or slag build up on the surface of the sheet metal being cut.