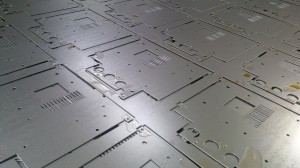

Ventilation louvres in sheet metal panels

Louvre tooling in a CNC punch press

Here’s a great view of a recent sheet metal project (June 2015) showing just what can be achieved with a Trumpf CNC punch press and tooling. We have an up-form louvre tool that has been used to press into the sheet metal (2mm Zintec coated mild steel) to produce a large area of ventilation. In this product some electrical equipment needed to be housed and could not be allowed to overheat so the louvre tool solution was perfect. The tooling used enabled a close pitch pattern of louvres to be pressed in both the x and y direction over the sheet without any stress or sheet distortion.

Tapping threads in mild steel sheet metal

CNC punched mild steel components with tapped threads

When producing thin sheet metal components we often have to produce points within the designs with threads. These chassis trays could have had M3 self clinch or anchour rivet bushes inserted which would have done a good job but there wasn’t room within the design. Luckily for us we have a Trumpf 3000R CNC punch press which allows us to form a plunged hole and then form a thread within the parent sheet metal all on the CNC punch press. The positions where this has been carried out is automatically lubricated and can clearly be seen in the photo.

Bent stainless steel sections

Stainless steel formed sections

When folding up stainless steel sections you need to have a CNC press brake that can deliver sufficient tonnage and tooling that can cope with the loadings produced. With our brand new Safan e-Brake 3M 100 ton machine we just such a machine. These 3mm thick stainless steel sections were needed as support sections on a large ventilation cover project we have be developing with our customer for the last few months and they were no problem for the Safan e-Brake. The ability to quickly produce CNC programs at the machine, in 3D if needed, is an advantage as well as the ease with which we can make alterations to bending programs and save them directly to our system server for use again when the projects repeat.

Safan e-brake with mild steel enclosures

Safan e-brake with mild steel enclosures

And here’s the new machine itself. We are pleased to invest in a new Safan e-Brake CNC press brake to go along side our other 5 CNC press brakes. This machine enables us to support bending up to 3M long now which is in line with the 3M x 1.5M sheet that we can cut on our Trumpf 3030 fibre laser cutting machine. Also, having increased pressing force to 100 tons enables us to fold thicker sections again supporting the increased material thickness that we can offer with our laser cutter.

June 2015 has been a busy month finishing off a busy year for V and F Sheet Metal with investments in a brand new CNC press brake, 2 new spot welders, a down draft welding ventilation system and an additional 3D Radan software licence. We are always trying to improve the service we offer our customers, please call us and see how we can help you with your sheet metal projects.