Sheet metal housings

3D software model

3D software models used to help develop sheet metal housings

Whenever we have a new housing that needs to be developed for a customer we use 3D sheet metal modelling software from Radan. We can easily create a 3D model (of either a single part or a complex assembly of parts) ourselves from scratch or import your 3D data in either SAT or STEP format. The 3D model can then be used to calculate all the correct blank sizes, hole positions and corner notches needed to produce the correct CNC punching or laser cutting programs. Once folded up on one of our CNC press brakes or fly presses the final part will replicate the 3D model.

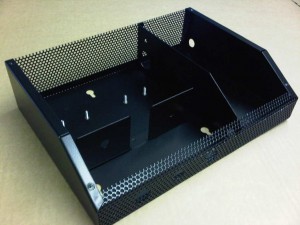

Mild steel spot welded housing

Spot welded mild steel light fitting housing

Here is a great example of a sheet metal housing we manufacture for a UK lighting company. The housing has so many different manufacturing techniques needed to produce it including CNC programming, CNC punching, de-burring, CNC bending, bush and stud inserts pressed into place, spot welded fabrication and powder coating with the bush and stud threads being masked off to stop them filling up with powder when coating. The perforated sheet metal end plates act as added ventilation for the light fitting housing and have been CNC punched out of pre-perforated mild steel sheet. This sheet metal housing holds all the electrical control gear needed to drive a fibre optics bedside lighting unit often used in hotel bedrooms.

Aluminium light fitting housing

Aluminium light fitting housing components

This light fitting housing was again developed in Radan software using the 3D modelling tools to ensure all the fixing holes lined up and the cover of the housing correctly fitted over the body of the housing. The housing assembly was complex and many points had to line us correctly with bushes and screw clearance holes. Some of the countersunk holes were produced in our CNC punch presses using form tooling allow us to press the countersink form in 1 second. The blue and green plastic coating the aluminium sheet is to help protect the surface and reduce scratched in production. Once the housing parts have been finished they have the plastic film removed and then silver anodised.

Welded aluminium housing

Sheet metal fabricated housing

Strong sheet metal housing constructed from aluminium. All the corners have been fully seam welded together with various plates inserted into the housing. Once again, 3D software helped us to develop all the correct sizes needed to manufacture the housing and to produce 2D drawings with inspection points. With all these housings whether they are just folded up to fit together, spot welded fabrications and fully welded the importance of producing the correctly sizes parts starts from accurate CNC punch press or laser programming. If you have a housing that needs to be manufactured from sheet metal we will have the right approach to produce the housing efficiently, accurately and at a price that will help you be competitive, please give us a call or send you drawings to us for a quote.