Laser cutting mild steel components is the perfect process for manufacturing batches of sheet metal work.

3D Model of a mild steel bracket generated in Radan CAD/CAM sheet metal software

Nearly all our sheet metal work that has folds starts with a 3D model. It could be one supplied by our customers in a STEP / SAT or IGES format. This is great as it saves time not only when programming to manufacture the components order but also when initially preparing quotations. If our customer doesn’t have a 3D model or one that we can open then we will generate the 3D model ourselves. By using our Radan CAD/CAM software we can produce a 3D model and link it to the correct material databases to aid the calculation of cut sizes and tooling for laser cutting or CNC punching.

The process can go the other way with us creating a 3D model and providing our customers with images or DXF files if the need them.

Image of a laser cutting nest of components showing efficient use of material

Once the 3D model has been created and unfolded the individual parts can be “nested” together to produce the best sheet utilisation possible. The Radan software calculates this with one click of a mouse and in seconds. We can then experiment with the orientation of the components on the sheet as well mixing several different parts together to reduce material wastage. That said, the vast majority of the time the software gets it right and cannot be beaten by human intervention.

As well as creating an efficient nest of parts the software also enables us to produce a CNC program which drives the laser cutter to produce the components with the shortest cutting path.

Laser cutting path simulation generated within the Radan software

Along with the automated best path we can intervene to cut parts in a certain order or tag certain parts in place or allows others to fall through the machine bed and then collected by a conveyor belt system. This ability to tune the program to suit the component size, material and profile makes this software very powerful, we wouldn’t be without it. This is especially useful when laser cutting a range of different parts from the same sheet of metal. The laser machine operator can also take an active role when using off-cuts of materials on the shop floor. The operator can select a piece of material and then take parts from a programmed nest and make them fit the material without the need to involve the office. This speeds up the production of samples and trial components on the shop floor for new projects.

Mild steel sheet on the pallet changer waiting to be laser cut

The components discussed here were laser cut from 2M x 1M sheets of mild steel 2mm thick. They were loaded onto the automatic pallet changer system as shown in the photograph. This system allows a sheet of parts to be laser cut while a sheet is waiting to be loaded. Once that sheet is finished it’s automatically switched over enabling the operator to remove parts while the next sheet is being laser cut. This simple system enables us to maintain a high laser cutting rate which saves time and cost prices.

If you look carefully you can see our Trumpf 200 and Trumpf 3000 CNC punch presses in the back ground of the photo. Acting together with our Trumpf 3030 fibre laser they make a great team and allow us to take on a wide variety of sheet metal work.

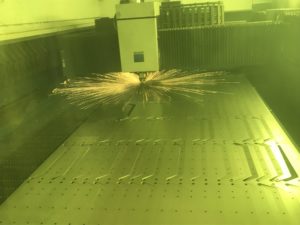

Laser cutting 2mm mild steel – sparks generated from piercing holes

So now we are at the point of laser cutting mild steel components. You can see a sheet full of cut components and the fibre laser machine right in the process of laser cutting through the 2mm mild steel sheet. The sparks are instantaneous and are normally associated with the point of piercing through the material. Once through the laser can cut a hole or edge profile very cleanly. These parts were cut with pure nitrogen gas producing a very clean edge. The final parts needed no further cleaning up before they were powder coated.

Laser cut nest of mild steel components waiting to be removed from the parent metal sheet

If you click on the photos here you will see in detail just how cleanly the components have been laser cut. Virtually no distortion, burnt edges and no burring. Processing materials as cleanly as this saves us a lot of time in post op finishing and improves the consistency of components throughout a batch. You can also see just how thin the laser cut line is, well under 0.5mm thick. You also see how well the parts have been nested together to reduce material waste.

Clean cut from a fibre laser cutter using pure nitrogen gas

Laser cutting mild steel components such as these really shows how easy it is to produce components with a smooth clean finish and simply get the best from a sheet of metal. This is important when working with 2mm mild steel but even more so when cutting expensive materials like aluminium, stainless steel, copper or brass. All materials that are easily processed with a fibre laser cutter.

Laser cutting scrap skeletons waiting to be recycled

Once all the laser cut components have been lifted away from the parent sheet the material that is left is called the skeleton. This residual sheet material can easily be lifted from the bed of the machine and folded up. The material is then kept with other off-cuts of the same grade and then recycled. All the waste sheet metal materials used by us to produce our customer orders is recycled, nothing is wasted.

Final laser cut mild steel components waiting to be folded

The final components are simply checked, stacked and then are ready for CNC bending. Components like these are easy for us to produce and are very much part of our everyday production plan.

If you have laser cutting mild steel components already drawn up please send us your drawings to sales@vandf.co.uk and we will be happy to produce a price for you and get you started.

For more specifics on laser cutting mild steel components or any other materials please read our web page “what is CNC laser cutting?“