CNC bending using modern press brakes

V and F Sheet Metal have been manufacturing in Southampton for over 35 years. A family firm who have invested over many years in CNC sheet metal manufacturing equipment. Sheet metal CAD/CAM software and tooling.

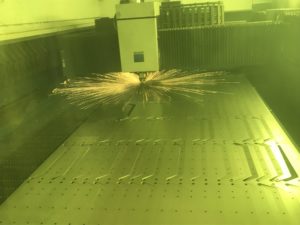

If you are based in the Southampton area and are looking for sheet metal work, give us a try. The images her shown us working on a wide range of projects. Folding aluminium channels on a small CNC press brake. Folding mild steel housings on our 3M long CNC press brake. TiG welding aluminium boxes. CNC punching zintec brackets and laser cutting stainless steel handles.

Laser cutting 2mm mild steel – sparks generated from piercing holes

Whether you call is manufacturing, production, fabrication, engineering etc. It’s still the process of taking raw materials and transforming them. Manufacturing can be laser cutting complex shapes from mild steel. Perhaps to be used as the starting point (a blank) for a wall fixing bracket. It could be CNC punching aluminium strips that will be rolled and welded together to make rings. Again, manufacturing might be folding and then welding stainless steel pump housings for the pharmaceutical industry. They all take materials and process the in some way.

If you are looking for manufacturing in Southampton and surrounding areas whether it’s just a new part or many thousands we can help. We often work on batches of 25, 50 or many hundreds. Call offs and special projects can also be catered for. With a long history of working in partnership with other suppliers we can offer the complete manufacturing service.

Folding up of components – Manufacturing in Southampton

Perhaps you have a manufacturing project that needs sheet metal work but more than just that. You might have machining requirements, for instance milling and turning. Maybe you need parts or assemblies to be painted, powder coated or silk screened. Treatments such as zinc plating or Iridite NCP dipping. We can manage the whole project to give you a finished manufactured solution.

TiG welding aluminium housings

Using the latest CAD/CAM manufacturing software we become part of your team. Taking your ideas, drawings and 3D models. We can clean up details and test out ideas ready for manufacturing before cutting any materials. If you wish we can feed back updated 3D models and 2D drawings or flat blanks to help your design function.

Trumpf 200 CNC punch press producing zintec sheet metal blanks

Manufacturing in Southampton we are ideally placed to delivery same day from Dorset, Hampshire and Sussex. As well as Wiltshire and Surrey. Further afield is no problem with overnight parcel and pallet services all over the UK.

If you have a design project that needs sheet metal manufacturing please let us know. Our team are always happy to chat and help refine your designs. If you want some price options please e-mail your drawings and we will be happy to do some calculations for you. File formats that we are happy to work with include PDF, SAT, STEP, DXF and DWG.