Sheet metal fabrication manufacturing using CAD/CAM software and CNC punching

I thought it would be useful to explain in a little more detail the processes we go though as a sheet metal fabrication company when taking information from our customers and producing sheet metal fabrications by CNC punching on our Trumpf CNC punch presses.

The whole process can be broken down into 10 basic stages from receiving the basic design information from our customers to the final CNC punched components.

Stage 1. A 3D software model is created of the sheet metal component or assembly

The design information we receive from our customers can be in many forms but the most common are 3D STEP files, 3D SAT files, 2D DWG and DXF drawings, simple PDF files or still occasionally printed paper drawings. Sometimes our customers will be give us a sample sheet metal component to copy or adapt to their specific needs on a particular project. Most of the time if the sheet metal fabrication is not just a simple flat component we will create a 3D model as the starting datum for the project. This enables us to examine the assembly fit of several associated sheet metal components that might have to work together for instance a sheet metal folded box and a cover where the fixing holes need to line up. We can feed this design information back to our customers to be checked out with their non sheet metal parts before we start any actual manufacturing. This can also be a help for our customers in checking their own designs and we can at this stage feedback possible design improvements to help with production and reducing the sheet metal component price.

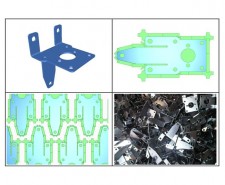

Stage 2. Developed flat 2D sheet metal blanks from the 3D model

The 3D software model of the sheet metal component is used to create an ‘unfolded’ developed flat blank of the part. At this stage all the manufacturing information such as material type, sheet density, sheet thickness and corner bend radii will have to be correctly applied to the sheet metal component model to create the correct bend sizes. Once done correctly this will enable a sheet metal component to be CNC bent and to fold up back to the correct sizes to match the original 3D design model. This has a great advantage for us as do not have to try out sample sheet metal parts before batch production of sheet metal work as all the trial and errors can be carried out within the software, thereby saving material costs and time.

Stage 3. Developed sheet metal blank profile is cleaned up with any inspection information added to aid shop floor production

The next stage is to refine any corner notches that will not fit standard CNC tooling, check that all the details on each face of the box are correct to the 3D model and add any required inspection information that might be needed to the manufacturing processes for the sheet metal fabrication.

Stage 4. Sheet metal parts are CNC punch press tooled

The Radan software we use can apply a standard CNC tool library that we have built us over many years to try and match features in the sheet metal component with the correct CNC tooling. The library of existing parts can be seen on the website under the tooling sections. This is the stage where the skill of the CNC programmer is also required to ensure the correct CNC tooling is selected and the least number of hits is used to produce the most efficiently CNC punched part. This is also the stage where we have to decide how the sheet metal work will be removed from the parent metal sheet. It may be tagged at its corners and then removed by hand, CNC punched completely out of the sheet to be removed by hand or CNC punched out and allowed to drop through a chute in the bed of the Trumpf punch presses into a collecting bin below. This method is usually best applied for small sheet metal parts that may not have an important cosmetic surface finish. There is a video link of our Trumpf 3000R CNC punching some mild steel bracket through the machine chute straight into a bin below.

Stage 5. The sheet metal components are CNC nested for the best sheet layout within the parent sheet

Our Radan CAD/CAM software nester utility is then used to find the best fit of the parts from a given sheet of metal. Odd shaped parts can be fitted together and smaller parts CNC punched from the gaps between larger sheet metal parts or even from within another part’s window features. The better the fit that we can achieve at this stage the higher the sheet metal material yield the cheaper the final part price will become. This has become all the more important with more expensive materials such as stainless steel, aluminium alloys and brass or thicker sheet materials. With the Trumpf CNC punch presses we can program to produce sheet metal work from between the machine clamps enabling still more components to be squeezed from each sheet of metal.

Stage 6. CNC punch press tooling clearances within the sheet metal CNC nest

The software is also used to check that all the CNC tools and individual sheet metal components are not overlapping each other. It is also very important that the CNC nested metal sheet is stable enough in production to hold together whilst being CNC punched at speed on our Trumpf punch press machines.

Stage 7. Order text is generated to guide the CNC punch press production in the correct order of production

The exact order that the individual CNC tools are punched into the sheet metal can be controlled which is important if you have forms in the sheet metal fabrication such as dimples, louvres, tapped plunged etc as they need to be CNC punched after any other holes or they will be damaged by the head of the Trumpf machine moving over them.

Stage 8. CNC production verification is carried out within the CAD/CAM software

This stage of the CNC programming allows us to see within the CAD/CAM software what the Trumpf CNC punch presses will do when the sheet metal is being punched. At this stage any strange movements of the parent sheet metal can be corrected to give the most efficient and the safest punching path is production.

Stage 9. CNC punch press code blocks are generated

The ‘blocks’ are automatically written as the code needed to talk to the Trumpf CNC punch presses to instruct them when to punch, which CNC tooling to use, the sequence that the CNC tooling is used in and where to punch on the metal sheet. This code should need no alteration by us as Radan automatically writes this code based on the order text written in step 7.

Stage 10. Final manufactured sheet metal fabrication

The final part after CNC punching, de-burring and CNC bending. The sheet metal work is now finished.

For more information on sheet metal work and how it’s made please take a look at this in depth review.

V and F Sheet Metal, 28 Brunel Way, Segensworth East, Fareham, Hamsphire, PO15 5SD