3D Sheet metal software modelling

When working with any complex sheet metal component we tend to start with a 3D model in our Radan CAD/CAM software system. The 3D model is created with reference to the material type, material thickness, profiles sizes, hole sizes and hole positions. Once the 3D model is complete it can be used to check hole alignment with other sheet metal parts that we may be manufacturing for our customers. At this stage it’s easy to see if there is a problem with the 3D model or our customer’s drawings and report back to them before committing to laser cutting or CNC punching any sheet metal material. We can either send the 3D model as CAD data in a *.SAT or *.STEP format. For customers who don’t have a 3D facility themselves we can offer 3D images and 2D CAD data in a *.DXF or *.DWG format. Once the model has been approved it is used to create the flat pattern needed for manufacturing.

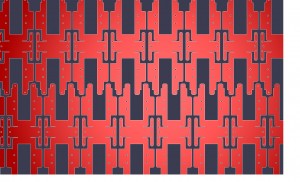

Laser cutting part layout nest

Having created the 3D model in our Radan CAD/CAM software, unfolded it and tooled it up ready for cutting we have to obtain the best fit of the flat blanks within a standard metal sheet size. The most popular commercially available sheet sizes are 2m x 1m, 2.5m x 1.25m and 3m x 1.5m but we can always use small off cuts from other jobs of buy in special blank sizes for production jobs to reduce material waste on awkward shapes. The CAD/CAM software automatically finds the best fit taking into account the grain direction on the sheet. We can always intervene if we want to change a position of a component or can see a more efficient nest layout. Once the component layout has been completed, which normally takes just seconds, we can create a compiled file which is used to drive the actual laser cutting machine to cut the components required.

Laser cutting the chassis brackets

The laser cutting program that is generated from the CAD/CAM software instructs the machine setter in what material type is needed for the job, it’s thickness, the laser cutting assist gas that will be used and the nozzle size needed to produce a clean laser cut edge. The software takes most of the decisions and makes the Trumpf 3030 3KW fibre laser cutting machine set up from one job to another a simple task, often being just a matter of minutes. Once the material is loaded onto the pallet changing bed of the machine the operator can cut a component, stop the machine, check the part for size and edge cut quality and then run the production batch needed to satisfy the order. The whole laser cutting process is automatic and carried out inside the machine with the machine operator only able to view the laser cutting process through a special filter glass window.

Another advantage of using a laser cutter to produce sheet metal blanks is that there is no tool clamping zone on the sheet so the laser cutting head can cut over the whole sheet leaving very little waste material, which all adds up to more competitive piece part prices for our customers.

If at the end of a production run more sheet metal work is needed to complete an order the laser machine setter can create his own program at the machine for a small quality of parts with the need to create more full programs.

Fast Tube by Casper

Please click of the video to see our Trumpf 3030 in action laser cutting the sheet metal nest illustrated above. The video has not been speeded up this is the speed that it cuts 1.2mm zintec with compressed air.

Laser cut chassis blanks ready for bending

The laser cut blanks are produced from 1.2mm thick zintec sheet with 20 being cut from a standard 2mx1m sheet. With the Trumpf 3030 3KW fibre laser we have the option of laser cutting using either Nitrogen, Oxygen or compressed air. The Nitrogen gas is used to produce a clean cut edge as it’s inert and prevents oxidization while the material is cut. It’s perfect for aluminium, stainless steel and mild steel along with its zinc coated derivatives. The Oxygen gas is used when thicker steels need to be cut e.g. 5mm and upwards or when parts are zinc plated and the surface oxide is removed on the plating process. Compressed air is perfect for thinner sheet metal parts out of aluminium, mild steel or stainless steel. These zintec coated mild steel components were cut with compressed air which was perfect and the cheapest option of the 3 cutting gas types.

CNC press brake set ready for bending

Here is the tooling set up on one of our Trumpf 7036 CNC press brakes. The component is taken from flat blank to the final folded part is a series of bends across all 3 of the tools shown here. Once generated, the program to control the machine is saved away on our system server and is available for both CNC press brakes with interchangeable tooling making a flexible option when repeating batches. The CNC press brake control has a 3D graphical interface making it easy for the machine programmer to see if the component will be achievable with the tooling selected and also acts as a teaching aid to new operators when first folding a new job.

Finished sheet metal chassis brackets

After 3D software modelling, developed blank part generation, part nesting, laser cutting and CNC bending we have the final parts. In this case the parts were left un-finished in a zintec coated mild steel material which was more than adequate for our customer’s needs. If you want to see more videos of our laser cutting machine working or sheet metal manufacturing in general please visit our YouTube channel.

If you have a sheet metal work project that requires laser cutting or CNC bending please give us a call on 01489 577786 or send us an e-mail with your details and we will be happy to provide some quotes for you.