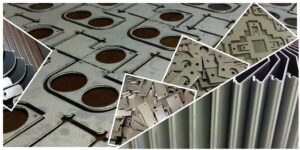

Sheet metal projects using a wide variety of manufacturing processes

We have a variety of ways to bend sheet metal. It can be just a simple single bend in a component to make an angle bracket. Several bends to form a box right through to very complicated enclosures with multiple folded features. Some parts can be an assembly of several pieces welded together to make a fabricated component. The assembly can then be made from several material thicknesses, shapes and sizes.

When we want to bend sheet metal, we must first make sure that we have the correct flat blank. This is created by a mixture of experience, software and trial and error. Samples may be run in house to test the shape and size of a blank before we bend sheet metal in production. Once the blanks have been produced by either laser cutting or CNC punching then will be ready for bending.

To bend sheet metal, we can use fly-presses, rolling machines and power presses but the most common method is to use CNC press brakes. These machines allow use to bend sheet metal parts in a consistent way using standard press brake tooling. With several machines, sizes and power ratings we can bend most sheet metal projects people need.

For more examples of past sheet metal projects please take a look at our Pinterest Boards

If you have a sheet metal project that needs to be manufactured, then why not send us your drawings to sales@vandf.co.uk

We can read files in DXF, DWG, PDF, STEP and, SAT formats.