Hampshire sheet metal workers

If you are looking for a sheet metal work supplier in Hampshire it’s well worth taking a few minutes to review the services offered by V and F Sheet Metal. From CNC punching, demonstrated here, to laser cutting, CNC bending and welding fabrications. We have a range of delivery methods to bring your work direct to your door or if you wish you are always welcome to visit us and see in more detail where your sheet metal work is manufactured.

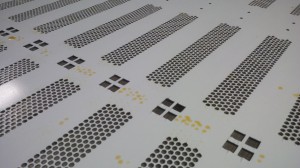

CNC punched zintec components

Just take a moment and click on this photo of a nest of CNC punched zintec coated mild steel chassis blanks produced for a pump mounting system. You can see in detail the amount of different shapes that can be produced with a Trumpf CNC punch press using simple standard rectangular tooling. Non of the examples show here in this blog post needed any new tooling when first being CNC programmed so the tooling cost to the customers in each case was zero. This is the case in the vast majority of sheet metal work that we produce here in Fareham, Hampshire using the flexibility of Trumpf CNC punch presses. Any of course we have the ability to put many components onto our Trumpf fibre laser cutter which never needs any tooling so the cost to get your work into production is very low even on small batches and prototypes.

CNC punched front panels for electronics components

A nice simple rectangular front panel required for an electronics assembly. Each front panel has been CNC punched around its outer profile with a 70.0 x 5.0 mm rectangle tool for the long sides and a 10.0 x 4.0 mm rectangle tool for the short sides. A technique called common line cutting has been employed around the outer profile to reduce the amount of punch press hits and material needed to produce each front panel. By sharing the tool cutting to produce a component and its neighbour at the same time time and money is saved and passed directly onto the customer through a cheaper part. With production of large batches every little advantage that can be produced is worth having and with smaller batched the importance lies with reducing the set up time needed to get a batch of parts into production. Luckily for us using Radan sheet metal programming software we can quickly try many different ideas and implement the one that is most productive across 2 CNC punch presses and a laser cutting machine.

CNC punched sheet metal with cluster tooling

With CNC punching as with all production processes time really is money. The longer we spend CNC punching your parts the more they will cost so what ever method we can use to reduce punching time is valuable to us and you. Be it common line cutting as above or in this case cluster tools they are all worth examining. A cluster tool is simply a fixed pattern of punches and a die with a series of holes to produce 2 of more holes with one hit. With the right combination of hole patterns a lot of time can be saved which can often pay for the tooling within a batch or 2 of production.

As with all the services we offer here from our factory in Fareham, Hampshire we try and supply a balance of design help, accurate production and competitive pricing to help you to keep production on the UK. Give us a call on 01489 577786 for more information or send you drawings to sales@vandf.co.uk for a design review or costing.