Sheet metal Enclosures

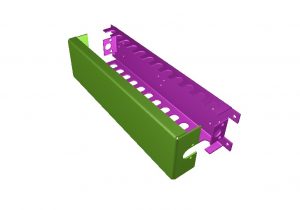

Today we’re looking at the production of metal enclosures. I think this process displays nicely the flexibility and time saving features of Radan software. So how do we begin the process? Well in this case the customer required production of a sheet metal enclosure using 1.2mm aluminium alloy. We always start with a 3D model on Radan, this allows us to make sure all the fixing holes line up before starting production. This model may come directly from our customer as a STEP or SAT file. If that is not available to us we will create the 3D model using our customers dimensioned drawings. Either way we have control of the basic design information needed to produce the correct developed blank shape and size.

3 D Radan model

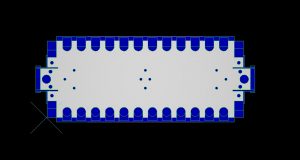

Developed blank in flat

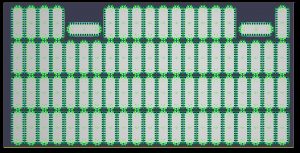

The developed blank shows the shape of the final enclosure in the flat (grey). The dark blue surrounding the blank is the shape produced by all the CNC punch press tooling. The tooling can be added to the blank shape automatically by the software. We still have the ability to alter this tooling to suit our own requirements where needed. Following on from this the blanks are set out on a full sheet of metal. In this case the sheet size is 2M x 1M. When CNC punching our Trumpf CNC punch presses can work with sheet up to 2.5M x 1.25M. Smaller panels can be programmed where needed for small components or smaller batches of work. This is definitely where the versatility of the Trumpf machine comes in to it’s own.

You might have noticed that the back 2 components have been turned at 90 degrees to the rest. Why so ? This is the region where the clamps hold the metal in place. Therefore the turning of these components is necessary but still allows for the maximum number of parts to be punched from one sheet. In addition, we have the capacity to to produce these parts on either the Trumpf 200 or 3000 as the same tooling fits both machines. A useful feature in a busy workshop, allowing production to be swapped from one machine to another.

Nest of parts

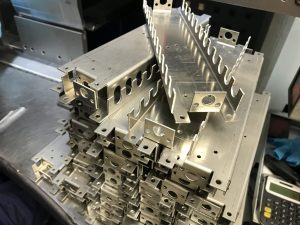

Metal Enclosures

Finally, once all of the sheet metal enclosure components have been CNC punched, we deburr the edges before moving on to the last stage which is folding. The image here shows a skilled employee folding up the components on one of our Trumpf 7036 CNC press brakes. By using the Radan software at the design stage, the final components should perfectly match the model. This allows us to save time and effort when making the first batch of samples or production. Any alterations can be fed back to the 3D model and subsequent 2D tooled CNC punching nests. This process can also be applied when a customer requires a design change to take place.

Folding up of components

Finished component

Please feel free to look at our website pages which gives up to date information on our plant list, tooling and design data. You have the ability to search all our blog posts so if this post doesn’t quite fit your needs then something else will! There is also an extensive gallery of photos.

If after reading this you think we could help you then please contact our engineering team at V and F Sheet Metal on 01489 577786 or drop us an email at sale@vandf.co.uk. We can’t wait to hear from you!